When renovating or remodeling a home, few things are as complex yet pivotal as identifying and potentially replacing load bearing walls. As literal pillars supporting upper floors and the roof, tampering with load bearing elements without proper precautions can profoundly compromise structural integrity.

This comprehensive guide covers what exactly load bearing walls are, how to identify them, techniques for safely removing them if necessary, expert recommendations, and more key information for homeowners.

What are Load Bearing Walls?

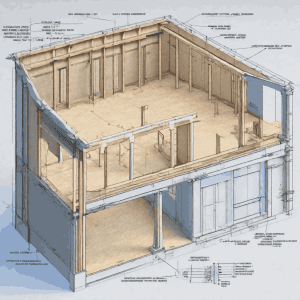

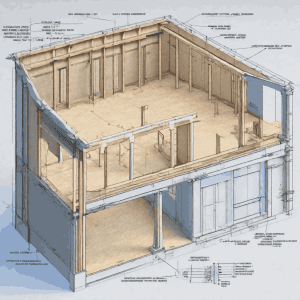

In construction, a load bearing wall is any wall specifically designed to carry vertical weight loading down through a structure. While ordinary walls merely divide spaces, load bearing walls play an indispensable role in the building’s overall structural support system.

The loads transferred depend on the wall’s location and can include:

- Weight of floors

- Floor joists, beams, and trusses

- Roof rafters and ceiling joists

- Upper story wall framing

- Snow, rain, and other forces acting on roofs

- Wind loads

In transferring immense downward forces from all these sources safely to the foundation, load bearing walls stabilize and prevent collapse of dwellings. They share the effort with supportive frameworks incorporating sturdy beams, posts, and columns.

Composition of Load Bearing Walls

Constructing load bearing walls requires robust materials:

Concrete: Poured concrete or concrete blocks have tremendous compressive strength ideal for bearing heavy loads in multi-story buildings. Reinforcing rebar adds tensile strength.

Masonry: Brick, hollow concrete blocks, or stone masonry walls also withstand compression well while channeling strains to footings.

Steel: Light gauge steel studs or structural steel posts embedded in floors provide reliable support in framed buildings. Sturdy tracks top and bottom connect to floor slabs.

Wood: Dimensional lumber including doubled-up wall plates sandwiching studs or engineered wood framing builds robust structural partitions in wood frame construction.

Thickness: Load bearing walls are usually thicker than standard 5 1⁄2” partition walls. Masonry types range from 4” concrete bricks to 8”+ concrete blocks. Wood stud walls may use 2×6 or 2×8 framing.

Proper joining techniques like overlapping wall plate ends or steel anchor ties also boost integrity. Walls buttressing the greatest roof spans tend to be most robust.

While thickness and construction materials hint at bearing capabilities, orientation and connectivity through floor levels definitively identifies load bearing status.

Why Identifying Load Bearing Walls Matters

In remodeling or renovation projects, determining if an existing wall is load bearing is one of the most crucial assessments before initiating any demolition.

Removing a truly load bearing wall prematurely or without provision of equivalent structural substitutions can profoundly compromise overall building stability. The consequences intensify over the number of floors:

One-Story Houses: Eliminating ground floor bearing walls may cause cracked drywall, sticking doors, or sagging rooflines as the weight above settles unevenly. But supervised repair is possible.

Two-Stories: The sudden strain redistribution could severely damage 1st floor load bearing elements as the full upper story load overrides capacity. Window and door frames twist out of the square from floor plate rotations.

Three or More Stories: Excessive downward forces may overwhelm remaining supports, causing extensive structural failure. Floor and roof systems descend unreliably, endangering inhabitants.

While even non-load bearing walls assist with lateral wind resistance, abruptly stripping them away also reduces building rigidity.

These worrisome consequences highlight why positively identifying Load bearing walls using reliable indicators helps avoid preventable, costly, and dangerous outcomes.

Common Indicators of Load Bearing Walls

While definitive determination of whether an existing wall bears structural loading often requires professional evaluation, homeowners can watch for strong visual clues:

Perpendicular Alignment with Floor Joists

Because load bearing walls transfer weight along vertical paths down through a structure, builders align them directly in line with bands of floor joists. This perpendicular crossing pattern maximizes solid load transfer.

So ceiling joist direction can hint at major ground floor load bearing walls underneath. Attic insights help trace wall orientation.

However, not every perpendicular wall automatically qualifies as load bearing. Checking other indicators is wise.

Tracing Interior Walls Through Floors

Continuous walls spanning upper floors reliably indicate load bearing function as they convey accumulated roof, wall, flooring, and snow loads downwards. Alignment between stories should raise suspicion.

Core structural walls around stairwells or flanking chimney flues also frequently endure vertical loading though offsets are common.

Of course, segmented non-load bearing partitions get built on each level to define rooms too. Differentiating these requires structural examination.

Identifying Thicker Exterior Walls

As homeowners visualize a house from exterior angles, thicker exterior walls signal high load bearing probability as they contain the building’s core framework. This is especially true of masonry or stucco finished walls hiding concrete block or double stud construction.

Heavy treatment around garage doors also hints at reinforced infrastructure.

Still, things like brick veneer facades, added insulation, or plumbing runs inside exterior walls could explain extra thickness too without actual load bearing utility.

Interior Walls with Masonry Construction

While wood or light gauge steel framing builds most partition walls, you may find substantial brick, concrete block, or stone elements in older houses or multi-story additions. These beefy masonry walls likely assist in bearing structural loads.

The immense weight and compression strength of such walls make them ideal for high load conditions – if in doubt, assume they are vital supports.

Fireplace chimneys may also include thick surrounding masonry walls to resist roof gravity and wind loads.

Columns Signaling Extra Support

Standalone columns integrated into partition wall framing provide clues that engineers designed that area to handle floor platform stresses in open concept zones lacking load bearing walls.

However, builders sometimes include decorative, non-structural columns simply for aesthetic cohesion. Tap on suspect columns to gauge whether they sound solidly anchored versus hollow. Checking connections in the basement may reveal if they indeed provide reinforced support from beneath.

Without removing wall finishes or probing underground, uncertainties around column structural contributions linger. Consider enlisting a professional building inspector to evaluate hidden traits methodically before modifying elements surrounding mystery columns. Their minor fee brings valuable peace of mind.

In summary, while the indicators above suggest load bearing probability in existing walls, additional research, testing, and structural examination is recommended before finalizing demolition plans involving these suspected supports.

Definitively Determining Load Bearing Status

For homeowners planning major renovations like combined living spaces or great rooms requiring removal of existing walls, having conclusive load bearing status helps avoid costly missteps. Here are common assessment methods the experts use:

Reviewing Original Architectural Blueprints

Builders generate specific home construction blueprints outlining structural supports like load bearing walls, beams, posts, and joists for permit reasons. So the original home plans provide the most authoritative reference for positively identifying load bearing elements.

But over decades, records get lost in transactions or possessions. Many homeowners lack their specific plans. Still, requesting records from the local municipal building department or researching filings by the initial architect or contractor may recover helpful specifications.

Blueprint analysis verifies which inner walls handle structural strains. Without stamped plans, assumptions remain risky.

Inspection by Structural Engineers

Where uncertainty lingers over the precise load bearing role of existing walls targeted for potential removal or modification, calling for an onsite structural engineering inspection adds an invaluable professional assessment.

Equipped with measuring tools, material strength knowledge, design experience and calculation software, the SE thoroughly evaluates:

- Wall alignments between floors signaling load paths

- Ceiling joist directionality indicating transfers

- Beam sizes, elevations, and connections

- Wall dimensions, wood grade, fastener spacing to gauge capacity

- Foundation specifications

Combining inspection data with permitted occupancy estimations and regional climatic factors like snow loads, SE’s determine suitable replacements or augmentation approaches. Homeowners gain well-advanted adaptations.

Though inspections cost several hundred dollars, they reduce expensive, unsafe guesswork. Structural issues discovered also protect inhabitants and mitigate lawsuit liability.

Wall Property Testing Techniques

Specialist building contractors possess various tools and methods for diagnosing wall structural capacities, including:

- Ultrasound – Transmitting sound pulses pinpoint voids or weakness behind wall finishes.

- X-ray – Detects metal framework, rebar, and block cores behind plaster or drywall.

- Radar and Microwaves – Maps structural components within walls using safe projected energy pulses.

They also perform in-situ strength tests:

- Hole Drilling – Assessing effort needed to drill inspection voids signals hardness.

- Insertion Probes – Instruments estimate strength from force required to penetrate walls.

- Hardness Rebound Hammers – Spring-loaded hammer recoil helps determine wall surface hardness.

Combinations of these techniques assemble detailed wall structural profiles. The data aids planning appropriate replacements.

Of course, costs can tally rapidly for exhaustive testing. But worrying about spending too little up front to conclusively identify load bearing elements risks paying exorbitant more down the road. Think long-term.

When Walls Defy Clear Categorization

In some home inspection scenarios, the load bearing classification remains stubbornly ambiguous after applying traditional identification methodology. Here are some special cases:

Partially Load Bearing Hybrid Walls

It is entirely possible for walls to carry loads over certain segments while other portions function nominally. One classic hybrid situation is metal post columns embedded at intersections of non-load bearing partitions and load bearing exterior house wrap to discreetly bolster targeted stress zones.

Wall finish concealment means hybrid traits stay hidden without invasive sounding procedures or demolition. Always consider nailing indicator plates over uncertain areas before rushing to remove finishes for temporary access during further analysis.

Inconclusive Load Magnitudes

Load bearing walls support static building loads transferred vertically through them. But the sheer load quantity itself falling on a particular wall – whether bordering on excessive or well within design limits – is not inherently obvious to the eye.

Worryingly for renovations, the line between easily reinforced and unsafely overloaded structural walls is also unclear absent detailed computations by structural engineers factoring:

- Building geometry

- Floor and roof square footage

- Material densities

- Standard occupancy

A sagging roofline or angled wall could hint at overload. Or undersized existing beams may overload flanking walls beyond their capacity. Regardless, professional assessment is advisable to quantify loads.

Outdated Structural Standards

Construction standards evolve across building code cycles to incorporate improved material specifications, weather data, occupancy projections, safety factors, and computation referents. This progress means newer methods satisfy modern structural requirements with less robust materials than decades past.

Knowing the exact year of construction provides clues about the vintage of structural assumptions to inform necessary replacement selections.

Seeking older home advice from historically-equipped architectural engineering firms proves constructive when evaluating aged load bearing elements.

In summary, exercise due diligence deciphering building structural capacity intricacies. Where doubts persist, enlisting professional guidance pays dividends prior to initiating wall modifications.

Replacing Load Bearing Walls with Supports

When interior remodels or upstairs additions require removing load bearing walls, adequate beam, column, or other supports must first reinforce the weight previously borne. Here are principal solutions:

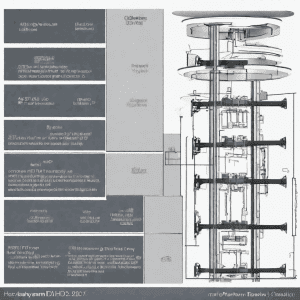

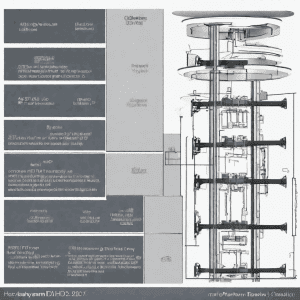

Level Insertion Beams: Horizontal flitch plate beams with laminated plywood sandwiched by two dimensional lumber beams make sturdy replacements for full-wall removals. Deep microllam or parallam engineered beams also work well. Steel posts often prop beam ends.

Inverted Lally Columns: Vertical specialty adjustable steel lally columns situated under beams at load points reliably bear roof weight removed from former wall zones. Concrete piers sometimes anchor column bases where stability is crucial.

Doubled Header Beams: Spanning over planned wall opening segments to continuously support joists or rafters on each side allows removing sections underneath while preserving stability. Glue laminated wood headers are common.

No matter the approach, temporary supporting walls near planned removal areas provide fail-safes as replacements get positioned. Severing suspected major load bearing walls into segments similarly reduces risk of destabilization at each sequence.

Load Bearing Wall Removal Techniques

Two principal methods prevail for replacing load bearing walls depending on access above or below the affected ceiling.

Above Ceiling Load Transferring

If sufficient access exists in unfinished attic spaces above the load bearing wall, this is generally the most direct replacement technique:

Steps include:

- Study approved architectural plans and structural report specifications for properly-sized beam requirements.

- Install temporary supporting frame walls and shoring posts near site to backup stability.

- Create a work platform along ceiling joists above the wall removal area.

- Carefully cut ceiling joists/rafters in planned beam pattern and install headers and jack posts safely bearing weight liability.

- Position new well-anchored horizontal support beam resting on sturdy vertical posts, aligned precisely with joist analysis.

- With the beam fully engaged, remove temporary ceiling supports and segment the underlying wall cautiously in planned sequence.

- Monitor for any unexpected structure shifts continuously and halt work if concerning signs appear.

Following above-ceiling replacement methodology according to approved architectural plans minimizes mishaps. Patience is mandatory.

Below Ceiling Mechanical Anchoring

When attic space for top-down replacement is encumbered, bottom-up installation fastens new supports directly to ceiling joists and raised foundations positioned precisely where load requirements dictate:

Steps involve:

- Include extra lifted interior flooring overharb for equipment maneuvering since overhead access is blocked.

- Install temporary walls nearby to shore up backup stability.

- Use hydraulic jacks to temporarily bear ceiling joists, then detach old walls at base and demolish fully.

- Leverage the jack height to cleanly install new horizontal beam with joist hangers secured and posts anchored to slab below per plans.

- Gradually release jacks safely transferring weight to new supports as alignment measurements confirm loading.

- Repeat steps along the desired expanse, removing remaining old wall segments once adjacent new supports are mechanically engaged. Do not rush the sequenced progression.

Obviously, lacking overhead access mandates caution hoisting elements from below to meticulous tolerances. Structural disturbances also require rapid correction which proves more difficult from underneath. Still, the technique enables conversions even in attic-less structures.

In both methodologies: work slowly, double-check everything, and banish assumptions by verifying measurements against architectural plans and engineering specifications. Patience pays unconditionally.

Step-By Step Wall Removal Guidance

When tackling load bearing replacement projects, indulge no temptation to skip steps that may seem unnecessary. Sequenced progressions ensure safety by preventingBuilder errors that jeopardize lives. Follow these guidelines:

Seek Professional Guidance

Support structure modifications require county building permits following mandatory consultations with licensed structural engineers and architects who supply project specifications and plans to comply with.

Erect Temporary Walls

Propping up temporary plywood-sheathed walls near the load bearing zone provides crucial stability insurance as you operate.

Create Equipment Access

Improvise overhead or underlying platforms that allow properly introducing temporary posts or beams to sustain structure weight removed.

Establish Redundant Support

Have additional temporary jacks or shims available for immediate placement if unexpected structure shifts occur.

Shore Up Secondary Impacts

Monitor cracks or splits in nearby walls as potential indicators of secondary load transfers needing bracing.

Remove Walls in Segments

Rather than dismantling the entire length rapidly, detach manageable disconnected segments of 3-4 feet judiciously allowing momentary stabilization between each.

Sequence Beam Connections

Follow architect plans precisely, connecting incremental sections of new beams or posts before removing additional wall chunks. Build supportive continuity sequentially.

Pause Work If Concerns Arise

Ground chatter, quivers underfoot, or opening cracks signal potentially worrisome stability loss. Stop immediately and mechanically shore sites before assessing cautiously. Have emergency numbers handy.

Allow Curing Time

Give adhesives, anchors, and cements full curing time to reach weight capacities rated on product specifications before removing additional wall sections. Patience pays.

By following these cautious site procedures and controlling the pace of removal phases, you reduce the risks inherent in dismantling major structural walls. Safety first.

Conclusion

Identifying, safely reinforcing, and optionally replacing load bearing walls stands among the most structurally significant processes in residential remodeling projects. Supported improperly during transitions, catastrophic building failures threaten.

But approached methodically with abundant preventative precautions guided by veteran industry authorities, ambitious contemporary renovations proceed smoothly while preserving family safety. Distribute loads meticulously. Temporary supplemental support buys insurance against missteps. And verify sequencing plans match final structural drawings.

By investing diligently upfront in comprehensive project plans from structural engineers and specialized architecture experts before permitting submissions, homeowners set removals up for success through smooth approvals and coordinated crew implementation.PLUS unexpected site complexities still arise on many jobs regardless, so extra contingency funds help address unforeseen needs without dangerous shortcuts.

Remember – no gust of new lifestyle convenience justifies risking household stability by shifting structural loads recklessness Reach out to consult an expert before modifying critical supports. The structural load monitoring equipment aids responsive value engineering.

With proper professional member structurals overseeing the choreography of load transfers sequentially, family homes continue standing sturdily for generations more, comfortably remodeled responsibly – now that’s structural piece of mind!

FAQs

What risks are associated with removing walls incorrectly?

Potential risks range from catastrophic collapse endangering life safety to incremental foundation cracking, brick loosening, or drywall seam failures making costly repairs inevitable down the road. Know limitations.

What walls can I likely remove safely myself?

Non-load bearing partitions not aligned with any roofing or floor beam structure above likely prove removable by capable DIY-ers. But verify independence through the attic first. Check catalogs for relevant safety guidance.

Will removing exterior front walls compromise structural integrity?

Potentially. Most exterior walls along the front or rear roofline provide essential stability under peak loads in those spans. Their moisture protection role also prevents decay. Avoid altering them without thorough professional input.

How much does load bearing wall removal cost?

Prices range enormously based on local labor rates, extent of modifications, necessary material upgrades, permitting obstacles, and specialty engineer design needs exceeding $5,000 potentially for challenging renovations. Budget conservatively.

Should plumbers replace old piping while walls remain open?

Absolutely, this presents the ideal opportunity to renew dated plumbing lines or ducting potentially requiring maintenance someday anyway. Just ensure the subcontractor properly straps lines to remain earthquake resilient long-term per code.

Where can I find affordable specialists to consult about my project?

Get neighbor referrals, check contractor ratings on Yelp, and verify consultant licensing and insurance. Explore NARI or AIA for members, unions for material discounts, and tap alumni networks for new practitioners. Consider overseas freelancers for affordability, ensuring data protection and adherence to local codes. Build a cost-effective team for wall removals, allocate ample design review time for safety, and prioritize quality assurance.

Can liquidators resell salvaged wall materials?

Absolutely – vintage brick, quality timber, or unique stone planks retain resale value for use in new construction or decors. Just safely detach intact portions without excessive cracking or loss of dimensional stability. Number each element and photograph final intact removal states thoroughly for future restoration purposes.

Research shows rising consumer demand for reclaimed building materials as sustainably-conscious designers popularize blended aesthetic looks celebrating the old and new. Proper storage and transportation handling minimizes further wear until collectors purchase the materials. Be sure to invoice demolitions contractors separately for the agreed value of any rare finds unlocked!

Are there high-tech options like robotics to replace manual removal?

Advancing construction robotics capabilities may help reduce risks inherent in manual load bearing wall elimination in coming years. Automated precision improves reliability. But current costs of leasing specialty equipment remains prohibitive for most residential renovation budgets.

The greatest advantages emerge in repetitious new builds where robotic arms excelling at consistent motion performance can frame durable partition walls around concrete molds pumped out by other machinery. Software interprets architectural plans for guiding sequential placements.

For now, bespoke home retrofit needs still require seasoned human judgment to adapt to idiosyncrasies not feasibly coded. But mobile apps projecting virtual blueprints registered spatially could soon direct targeted hammer demolition and rebuilding assists via augmented reality.

Should I save removed wall sections for memoirs?

Why not get creative? Clean scores along the top of a doorway fragment of the former wall could mount in the new opening as decoration expressing the dwelling’s history. Just seal amputated ends properly to prevent moisture damage ahead of creative reuse. Artistic lighting could also showcase an abstract rubble display.

Full sections work shelved decoratively in non-load roles as interior design elements or even exterior garden sculptures. However, check regional statutes – some municipalities prohibit housing demolished construction debris without processing due to particulate dangers. You decide!